Engine 1 - 150lbf Nitrous/Ethanol Liquid Rocket Engine

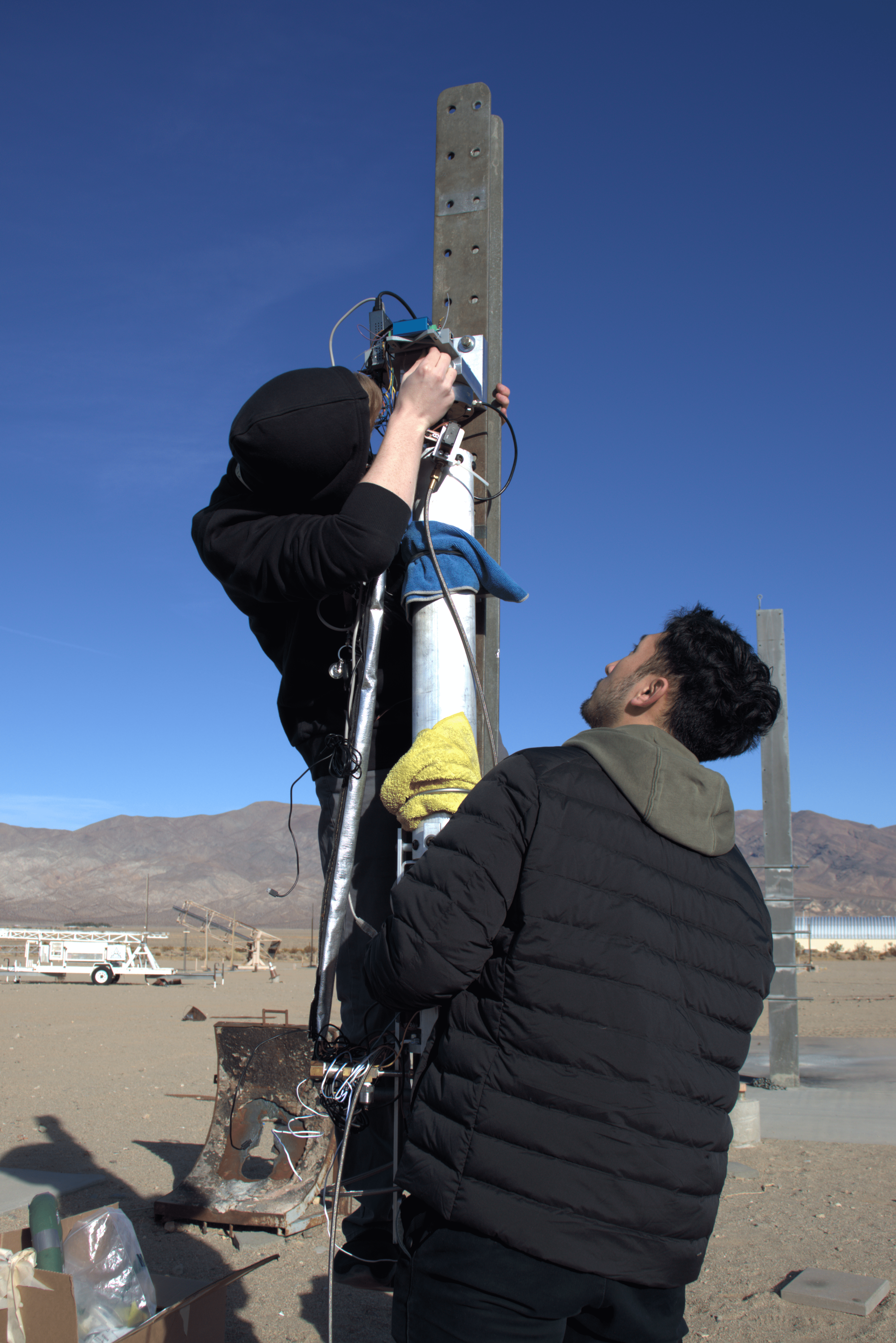

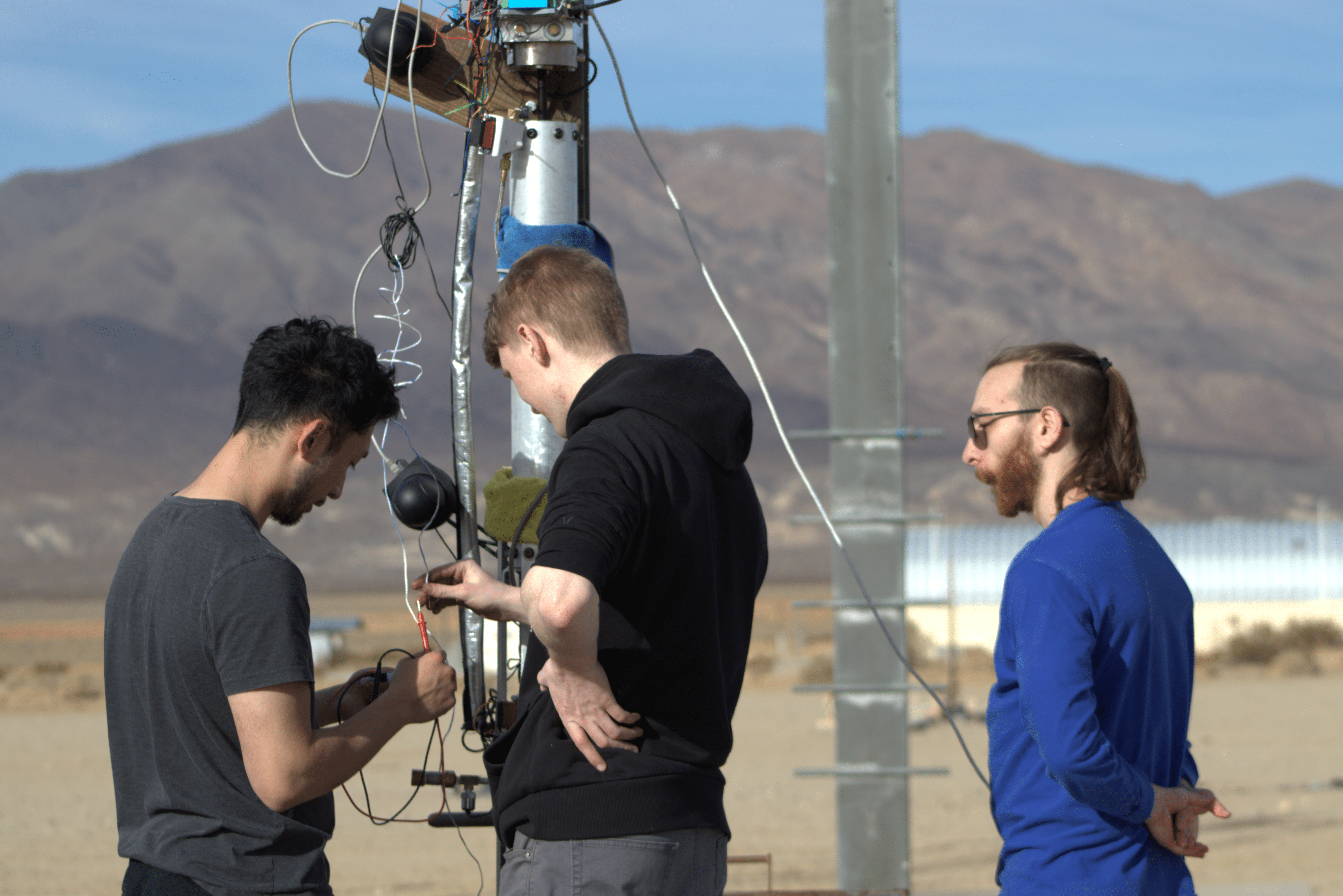

This is the first rocket engine made by Hornet Aerospace & Propulsion. It is designed to produce 150lbf, at 250psi and uses ethanol and nitrous oxide as propellants. This project was started sometime in the Fall 2023 semester, and was successfully fired in January 2025. The design is heavily based on Half Cat Rocketry architecture, as it is an excellent starting point for liquids. This engine was designed and manufactured at Sac State, and tested at FAR.

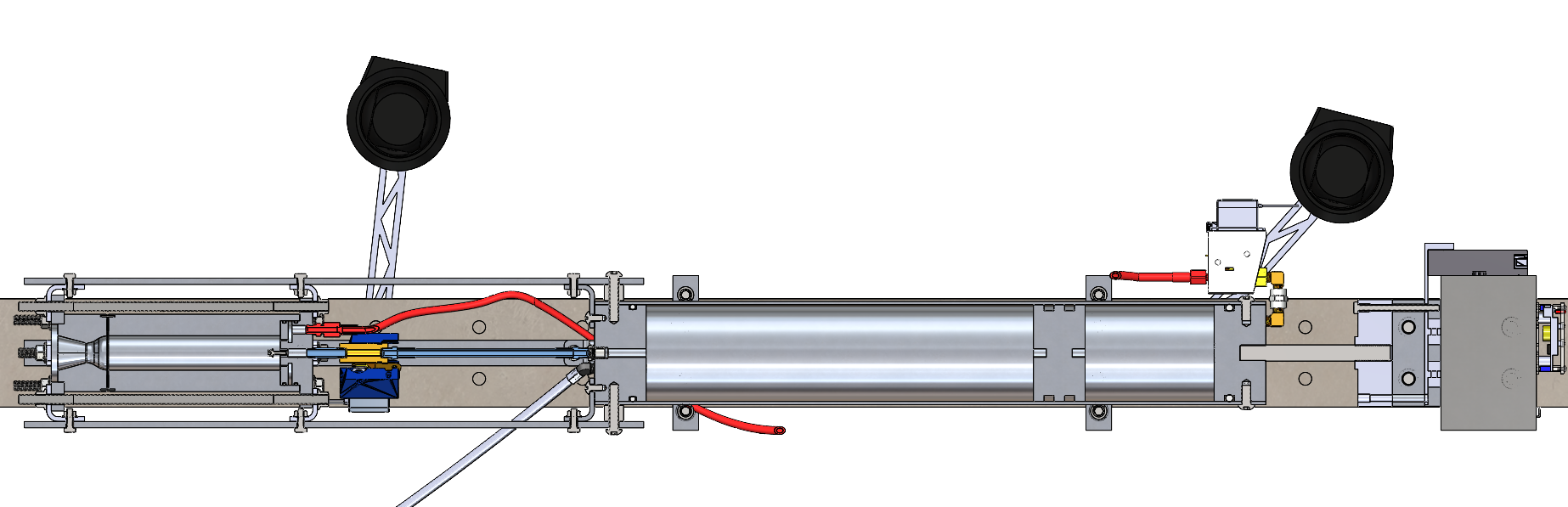

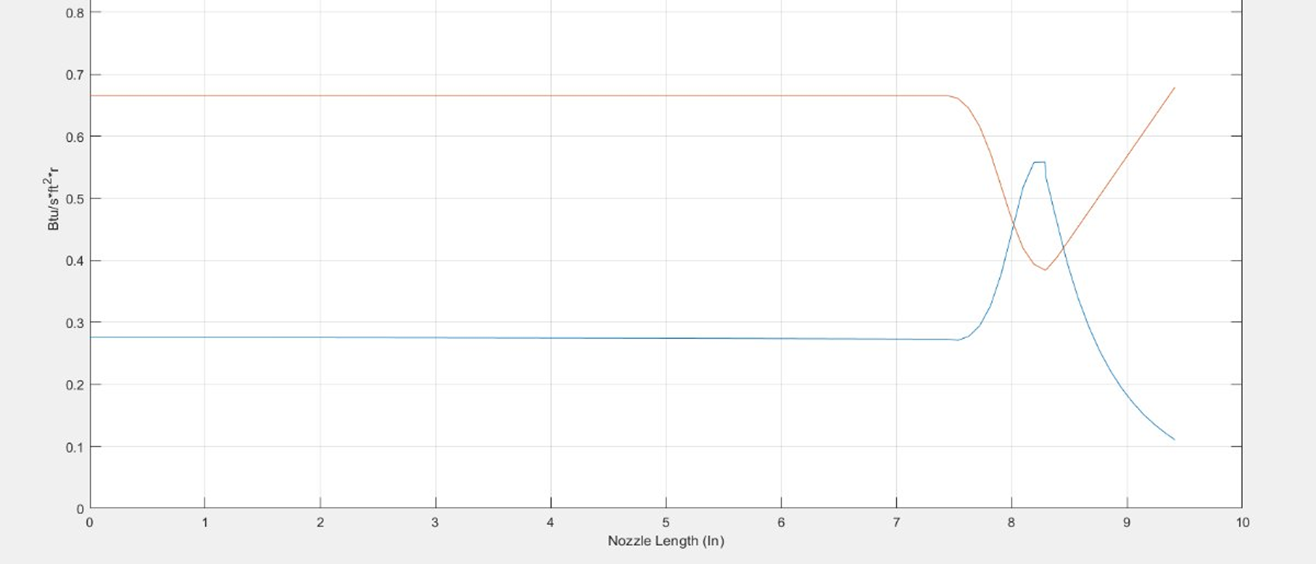

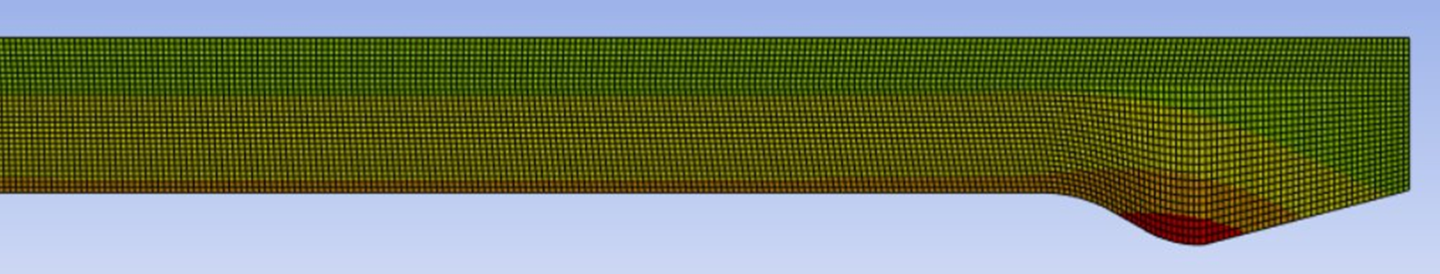

The thrust chamber does not have any active cooling built in, it relies on working as a heat sink to keep itself from melting. Heat sink cooling is when the inner surface of the combustion chamber conducts heat away from itself and into the outer surface, which keeps the chamber from melting. Eventually the entire chamber would heat up, and heat sink cooling would no longer work, in our case we designed the thrust chamber to be able to survive a 3 second burn. To calculate how thick our thrust chamber wall had to be to survive for 3 seconds, we first got thermodynamic properties of the combustion inside the chamber from NASA's CEARUN. These values were imported into a matlab script that solved for the heat transfer coefficient of the hot gas at each point in the chamber. This was then used to run 2D transient heat simulations in ANSYS Mechanical to find the minimum size of combustion chamber that could survive a 3 second firing.

The Injector is a Ox-centered scrintle, where the nitrous and ethanol are shot straight down, and the nitrous is redirected radially out towards the fuel streams by a flanged screw. The propellant tank was a tube with bolted bulkheads,where the nitrous is at the bottom and separated from the ethanol at the top by a piston.

Electronics

The electronics consist of a teensy 4.1 that controls 3 servo actuated ball valves, receives data from 3 pressure transducers and a load cell, and a relay for the igniter. There are also 3 cameras, everything is powered by two 12-volt batteries that sit on top of the assembly, and everything communicates to a laptop at the ground station via ethernet. The connection allows us to send commands, and to see live data and video from the pad. Data from the sensors is also stored onboard on a SD card in the teensy.